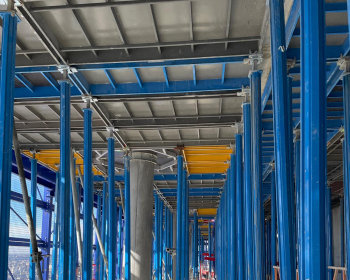

TopDalle Éco

The versatile TopDalle Éco system suits every type of building: offices, homes, retirement residences, hospitals, prisons, etc.

The work area is secured by full-surface Eco+ panels, preventing falls from height and the risk of tripping, slipping, or falling objects.

Installation and removal of Éco+ panels is performed from ground level

With theTop Perche, the formwork is set up and removed from ground level (no need for the rolling safety ladder).

Increased stability

The multi-support areas of the Eco+ panel, the continuous support extendable beam combined with the corner beam, provide optimum stability.

Protection from theft

The chemical process patented by Alphi prevents fraudulent recycling of aluminium beams.

Designed to limit CO2 emissions, the Éco+ panel is made of 100% recycled and 100% recyclable aluminium.

Short distribution channels

The production method implemented by Alphi favours operators in French industry.

Transportation is limited to national territory (distance between suppliers under 460 km).

Fewer lorries

Optimum packing has been achieved by limiting the thickness of the Éco+ panel and designing its shape for more compact stacking.

Lorries can now carry 15% more equipment.

30 m² / person / day at a height of 2.50 m

(formwork, adjustment, cladding and formwork removal).

Easy removal

The drop-head for fast removal integrated in the technical support (Alphi patented system) keeps the slab supported during formwork removal. The rotation of the aluminium structure is accelerated.

Surface continuity

• Working on a full surface facilitates mobility above the formwork.

• The continual adjustment of the extendable primary beam and the secondary corner beam lets you go near the edges of the cell.

Practical use

• Simplified assembly thanks to adjacent Éco+ panels.

• At the end of the span, the spacing of the Éco+ panel can be adjusted to the cell, leaving a 10 cm gap.

Easy identification

Coloured tips allow easy recognition of different Éco+ panel lengths.

The portable elements of TopDalle Éco are 20% lighter than traditional solutions.

The system limits manual load handling.

Less noise pollution

Éco+ panels have shock-absorbent plastic tips, which reduce noise.

Concrete formwork thickness

Above 80 cm, according to configuration.

Quality of concrete undersides

Deflection limited to L/400 (quality exceeding DTU 21 recommendations for concrete floors).

Nailing to wooden inserts

• Securing the plywood (15 mm authorised) by nailing.

• The asymmetric insert can adapt to different configurations.

Regulations

beams are designed in accordance with the NF 93-322 standard concerning formwork..

Cleanliness

The shape of the Éco+ panel limits laitance on the vertical wall.

Tests

All TopDalle Éco elements have been tested by the LOCIE laboratory at the University of Savoie Mont-Blanc.